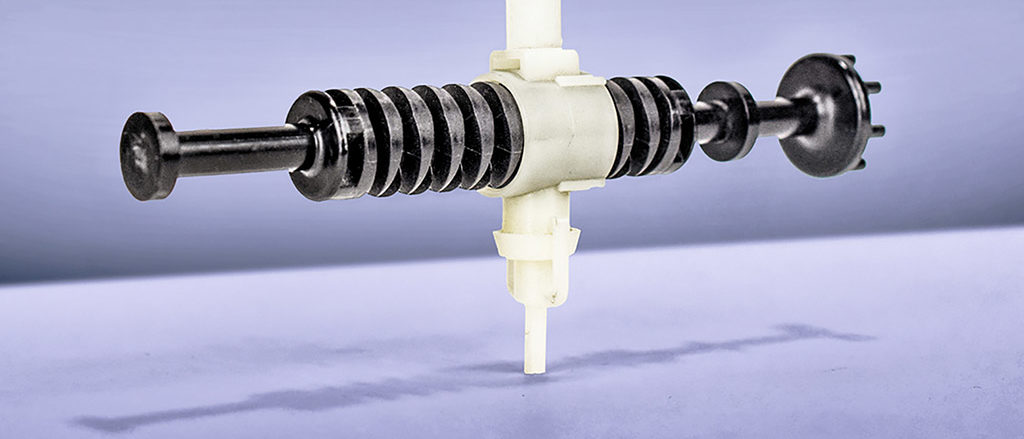

As part designs get more and more complicated the role of protoypes has become more and more important. The choice of materials continues to increase as do the number of processes available. From Selective laser sintering (SLS- nylon, glass filled nylon), Fused Deposition Modeling (FDM- ABS, PC, Ultem, PPSU), Polyjet printing( ABS – multi colored) to Direct Metal Laser Sintering (DMLS- Steel, Stainless Steel, Titanium, Inconel, and Aluminum). All of these process can provide that handful parts need to verify the design or do testing on.

As part designs get more and more complicated the role of protoypes has become more and more important. The choice of materials continues to increase as do the number of processes available. From Selective laser sintering (SLS- nylon, glass filled nylon), Fused Deposition Modeling (FDM- ABS, PC, Ultem, PPSU), Polyjet printing( ABS – multi colored) to Direct Metal Laser Sintering (DMLS- Steel, Stainless Steel, Titanium, Inconel, and Aluminum). All of these process can provide that handful parts need to verify the design or do testing on.  Should larger volumes of prototype parts be required then prototype molds can bridge the gap till production molds are built.

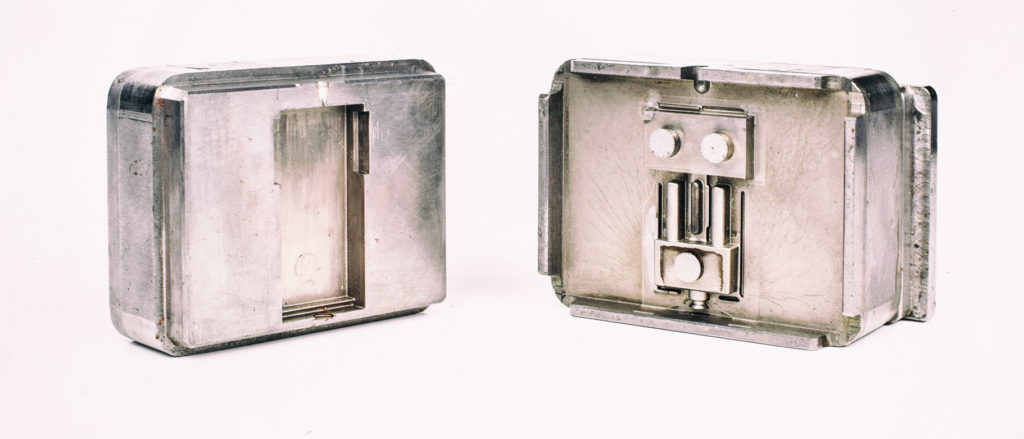

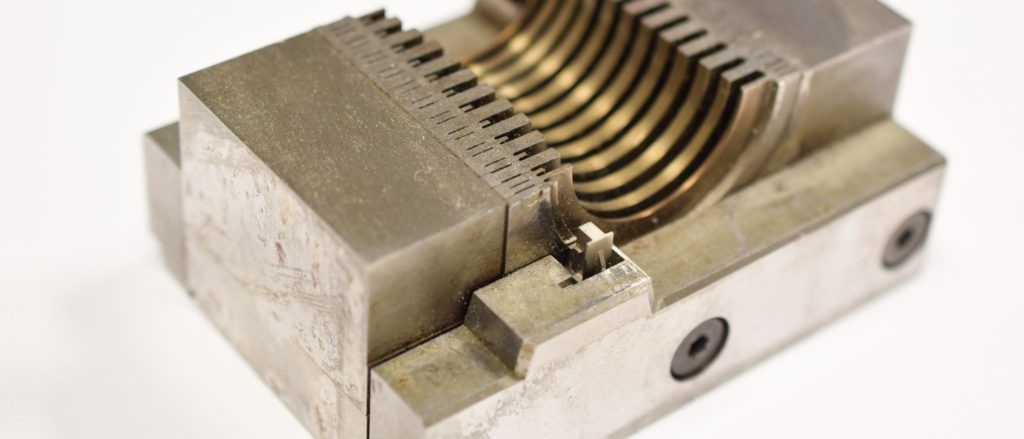

Should larger volumes of prototype parts be required then prototype molds can bridge the gap till production molds are built.

While International Plastics is a production house we understand the role that prototypes play in the product development cycle, and provide this service to our clients to help keep projects moving.