Plastic Replaces Zinc Diecasting

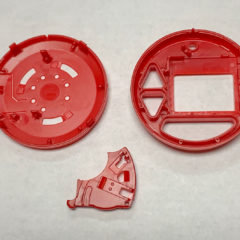

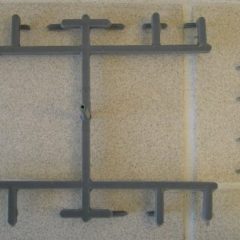

I was talking to the engineering manager at a good customer and he told me they were having huge quality and warranty issues with a zinc diecast gear they had been using. I told him of the success we had just had with another customer converting an assembly of components into a single high strength… Read More