A potential customer came to us needing prototype parts in a very short period of time in order to close a deal. They had been turned down by several of the large prototype molders for various reasons and were in jeapardy of loosing the business.

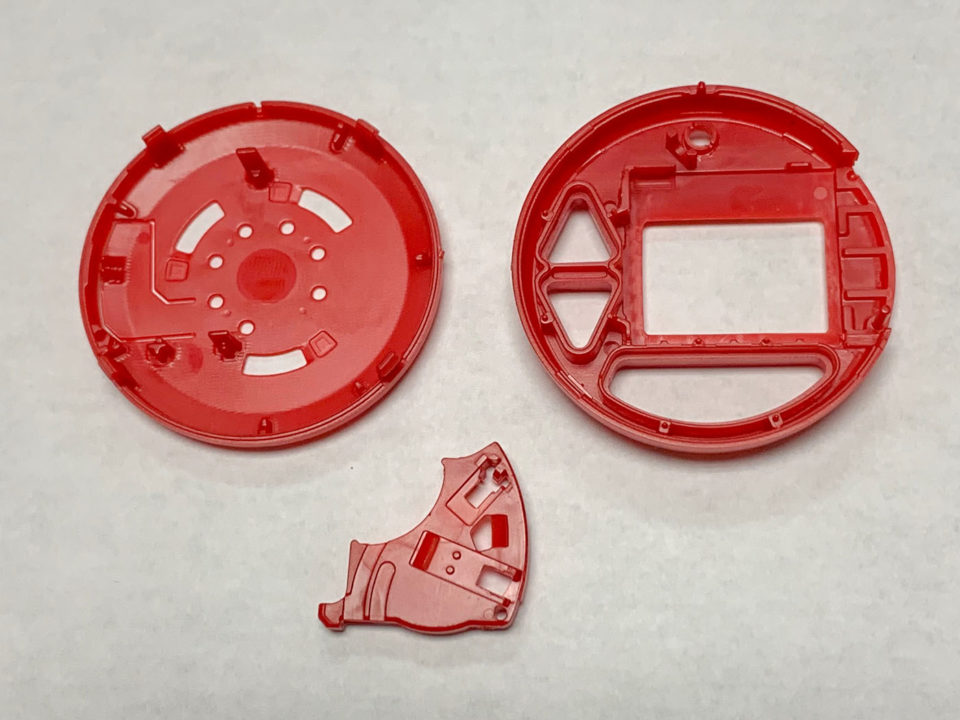

International Plastic’s solution was to build prototype cavities for three different parts using a modular proprietary mold system in 7 days. Most molders would see this as an opportunity to take advantage of the customer with an expensive mold price, expedite fees or outrageous part price. Not International Plastics. We charged a modest engineering fee and provided a thousand of each part at the normal production price, not an inflated prototype price.

The result? Our customer was able to get the contract from their client and International Plastics got new molding business.

The best part is, the International Plastics modular mold system uses hardened tool steel instead of aluminum, so the prototype molds could meet their production requirements without buying another set of production molds.

The modular mold cavities successfully produced hundreds of thousands of pieces throughout the entire life cycle of the product without additional mold cost.